The MariseaX Assurance: A Fully Managed, Integrated Supply Chain for International Buyers, Food Manufacturers, and Distributors

In today’s global aquaculture and seafood market, consistency and reliability separate successful businesses from the rest. Managing multiple suppliers, processors, and logistics providers across continents presents significant challenges in quality control and delivery assurance. MariseaX eliminates this complexity through our fully integrated supply model. We provide a seamless, single-source solution for premium Vannamei shrimp and Tiger Prawn (Penaeus monodon), managed from Indian farms directly to your distribution centre, with guaranteed quality at every transition point.

Our Foundation: Partnership-Driven Quality Management

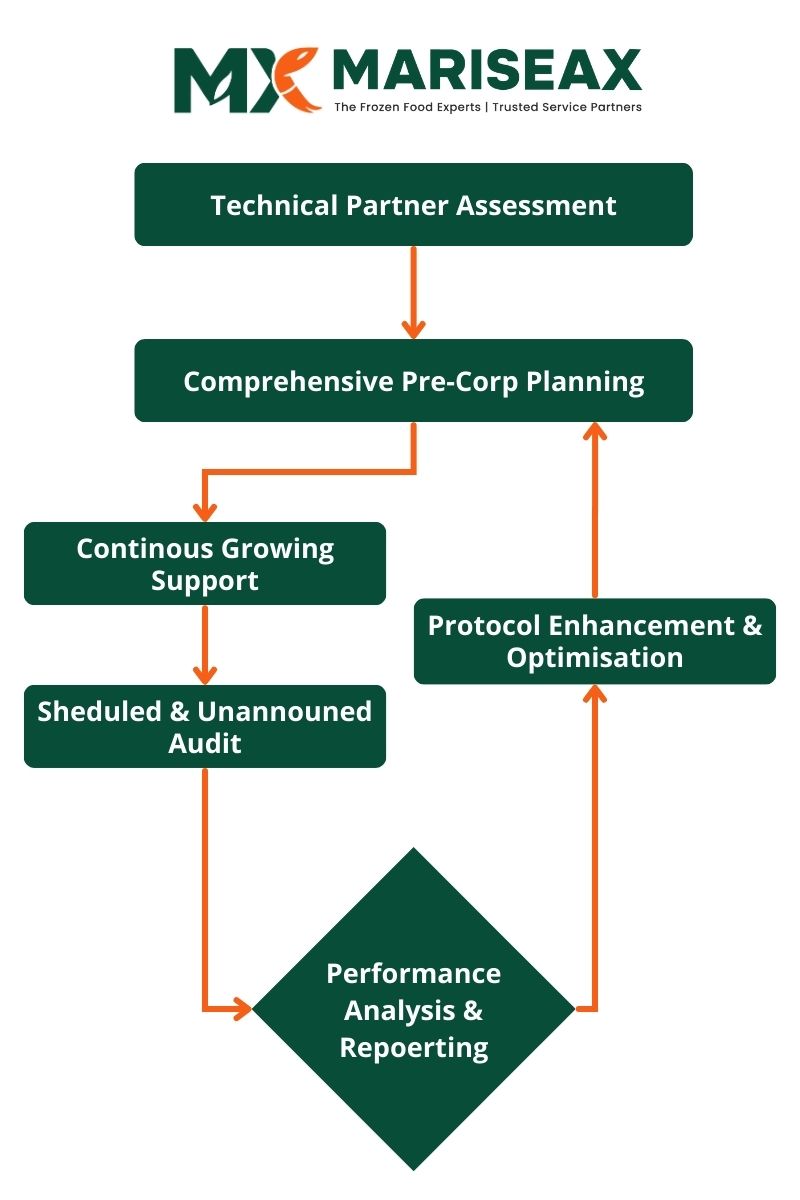

Quality begins at the source. Our comprehensive partnership framework ensures consistent standards through continuous engagement with our farming specialists. This begins with a rigorous cycle of technical management:

At MariseaX, we go beyond simple sourcing; we embed ourselves within the production process. Our dedicated team of aquaculture specialists works alongside our partner farmers, providing ongoing technical support and resources. This includes guidance on optimal feed management, water quality stewardship, and best practices for animal health.

This collaborative, hands-on approach is formalized through a continuous cycle of planning, support, and verification. It begins with Strategic Sourcing, where we partner with a certified network of aquaculture farmers across India, selected for their adherence to stringent biosecurity and sustainable farming practices. This ensures our partners’ success is synonymous with your supply’s reliability.

The cultivation of Vannamei shrimp itself is a precisely timed operation, typically lasting 90 to 120 days, with each phase critical to the final product’s quality.

The MariseaX-Supported Farming Cycle:

- Pond Preparation & Biosecurity: Before stocking, ponds undergo a rigorous protocol. They are completely drained and sun-dried to eliminate pathogens, followed by liming to balance soil and water pH, and filled with carefully filtered and treated water to ensure a bio-secure environment.

- Stocking with High-Health Post-Larvae: We ensure genetic resilience from the start. Our network exclusively uses Specific Pathogen Free (SPF) or High-Health Broodstock. The post-larvae are meticulously acclimatized before being stocked at optimal densities to promote healthy, uniform growth.

- The Grow-Out Phase: This period is defined by constant monitoring and management. Farmers provide scientifically formulated feeds, with rations carefully calibrated against the shrimp’s growth stage, biomass, and water conditions to achieve an excellent Feed Conversion Ratio (FCR). Simultaneously, daily monitoring of key parameters including dissolved oxygen, salinity, pH, and temperature ensures a stable and optimal environment for development.

- Harvesting with Care for Quality Preservation: Harvest is scheduled with precision. Shrimp are carefully collected and immediately transferred to an ice-slurry bath. This rapid temperature reduction, known as “thermal shock,” is critical as it halts metabolic activity, preserving the shrimp’s natural texture, flavour, and quality instantly after harvest.

This end-to-end oversight ensures that the superior quality of our shrimp is not just inspected at the end, but built into every stage of its growth, creating a foundation of excellence that is both reliable and sustainable.

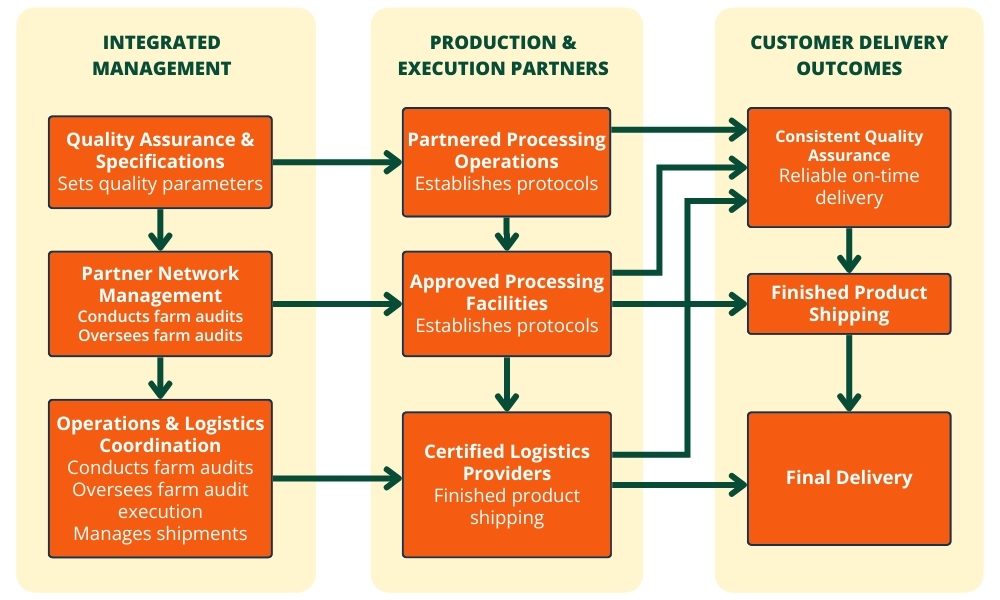

Complete Supply Chain Integration: Visible Oversight at Every Stage

Our integrated management model provides complete visibility and quality control across all operations. The following chart details our comprehensive oversight system and its connection points throughout the production and delivery process.

Comprehensive Service Management

- Quality Assurance System

Our quality framework begins with detailed specifications for size, texture, and product integrity. We implement rigorous checking protocols with comprehensive batch quality verificationat critical control points: during growth cycles, pre-harvest assessments, processing stages, and pre-shipment inspections. This multi-layered approach ensures consistent adherence to our standards for both Vannamei and Tiger Prawns. - Partner Network Integration

We maintain a carefully selected network of specialised partners:

- Quality Assurance System

- Farming Operations: Experts in sustainable aquaculture employing SPF broodstock and bio-secure pond management.

- Processing Facilities: EU and HACCP-certified plants implementing strict hygiene and safety protocols.

- Logistics Providers: Temperature-control specialists maintaining uninterrupted -18°C environments.

- Operational Coordination

Our management team provides continuous oversight through scheduled audits, process verification, and cold chain monitoring. We coordinate all transitions between partners to ensure seamless handling and perfect condition upon arrival.

- Operational Coordination

Business Advantages of Our Integrated Model

Partnering with MariseaX delivers significant operational benefits:

- Quality Consistency: Standardised processes and verification protocols ensure uniform product quality across all shipments.

- Supply Reliability: Managed partner relationships and coordinated logistics prevent disruptions and ensure on-time delivery.

- Complete Traceability: Documented verification at every stage provides full transparency from farm to final destination.

- Operational Efficiency: Single-point accountability and coordinated management reduce administrative complexity and resource requirements.

A Partnership for Sustainable Success

MariseaX represents more than a supplier; we are an extension of your quality assurance team. Our integrated supply model delivers consistently superior shrimp through comprehensive management, complete transparency, and unwavering commitment to reliability.

Streamline your procurement with a fully managed solution. Partner with MariseaX.

Contact us today to discuss your specific requirements and experience the advantage of integrated supply chain management.